In recent years, the Internet of Things (IoT) has revolutionized various industries by enabling seamless connectivity and data exchange between devices. In the realm of industrial automation and monitoring, the ESP32-based Controllers has emerged as a game-changer, offering an affordable and versatile solution for implementing Programmable Logic Controllers (PLCs). In this article, we delve into the capabilities of ESP32 as a PLC and explore its potential for automation and monitoring applications.

Understanding ESP32-based Controllers

The ESP32 stands tall as a robust and versatile microcontroller, boasting integrated Wi-Fi and Bluetooth functionalities that render it a prime choice for Internet of Things (IoT) applications. While it initially gained recognition for its prominent role in DIY electronics and serving as a staple in IoT prototypes, its prowess as a Programmable Logic Controller (PLC) has garnered considerable interest, especially within industrial domains.

Pioneering its way into industrial settings, the ESP32 has proven its mettle with a robust feature set. Equipped with dual-core processing capabilities, generous memory provisions, and a broad spectrum of General Purpose Input/Output (GPIO) pins, this microcontroller transcends its conventional boundaries. Its adeptness in replicating the core functionalities of a traditional PLC enables seamless execution of automation tasks and facilitates comprehensive monitoring functionalities within industrial setups.

The ESP32’s transformation from a stalwart in DIY electronics to a pivotal player in industrial automation showcases its adaptability and the expansive possibilities it offers. Its ability to emulate PLC functionalities not only streamlines operations but also paves the way for enhanced efficiency and reliability in industrial automation and monitoring tasks. This paradigm shift positions the ESP32 as a dynamic and versatile solution, expanding its footprint beyond the realms of prototyping into the intricate landscapes of industrial automation with unparalleled ease and efficiency.

Advantages of ESP32-based Controllers

- Cost-Effectiveness Traditional PLCs can be expensive, making them prohibitive for small to medium-sized businesses. The ESP32, on the other hand, offers an affordable alternative without compromising on performance. Its cost-effectiveness opens up new possibilities for implementing automation and monitoring solutions in diverse industries.

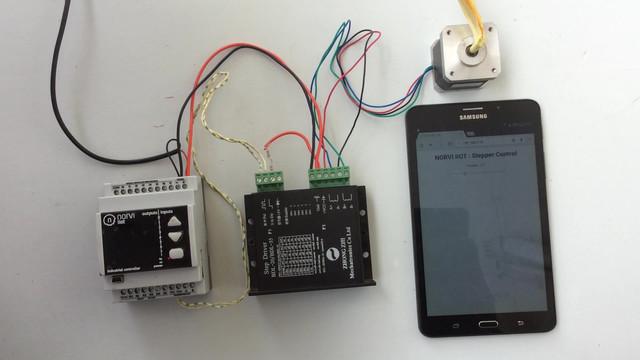

- Connectivity and Communication The built-in Wi-Fi and Bluetooth capabilities of the ESP32 allow seamless communication between the PLC and other devices, such as sensors, actuators, and Human-Machine Interfaces (HMIs). Real-time data exchange facilitates swift decision-making, enhances process control, and enables remote monitoring of industrial systems.

- Open-Source Platform The ESP32 platform is built on an open-source foundation, which means that developers can access a vast array of libraries and resources. This accessibility empowers engineers and developers to customize the PLC’s functionality to suit specific automation and monitoring requirements.

- Flexibility and Scalability ESP32-based PLCs offer immense flexibility in terms of programming and integration with various industrial protocols. Additionally, they can be easily scaled to accommodate changes in the automation process or the addition of new sensors and actuators.

Key Applications of ESP32-based Controllers

Industrial Automation In manufacturing environments, the ESP32 can serve as a cost-effective and efficient solution for process control, production line automation, and data acquisition. Its real-time capabilities and reliability make it suitable for controlling motors, valves, and conveyor belts.

Environmental Monitoring With the ability to interface with a wide range of sensors, the ESP32 can be utilized for environmental monitoring applications. From temperature and humidity sensing to air quality monitoring, the ESP32 can gather valuable data for analysis and decision-making.

Smart Agriculture In the agricultural sector, the ESP32 can play a pivotal role in smart irrigation systems, soil moisture monitoring, and automated greenhouse control. Its low-power mode and remote connectivity make it an ideal choice for off-grid agricultural setups.

Building Automation For building management systems, the ESP32-based Controllers can streamline energy usage, lighting control, and HVAC (Heating, Ventilation, and Air Conditioning) systems. The integration of a user-friendly HMI enables efficient monitoring and control of building operations.

Conclusion

As industries increasingly embrace the potential of IoT, the ESP32 emerges as a versatile and budget-friendly solution for automation and monitoring applications. Its cost-effectiveness, connectivity, and open-source nature position it as a promising PLC alternative for a wide range of industries. From industrial automation to smart agriculture, the ESP32’s capabilities empower businesses to enhance efficiency, reduce costs, and embrace the future of interconnected systems. By harnessing the full potential of ESP32-based Controllers , companies can usher in a new era of intelligent automation and monitoring.

Stay Connected to get updated news from NORVI: Facebook : LinkedIn : Twitter : YouTube

Read More:

Why should use ESP32-based PLC with Analog Inputs for Seamless IoT Integration?

Why NORVI-Arduino-based Programmable Logic Controllers?

Why should choose ESP32-based PLC with GSM to Enhanced Connectivity?